Reimagine, Recycle, Remake: the Future of Fashion is Circular

Brandix is on a mission to become the most sustainable apparel manufacturing company in South Asia. Driven by the desire to affect positive change, we are committed to using our influence in the industry to create a more environmentally conscious future for fashion.

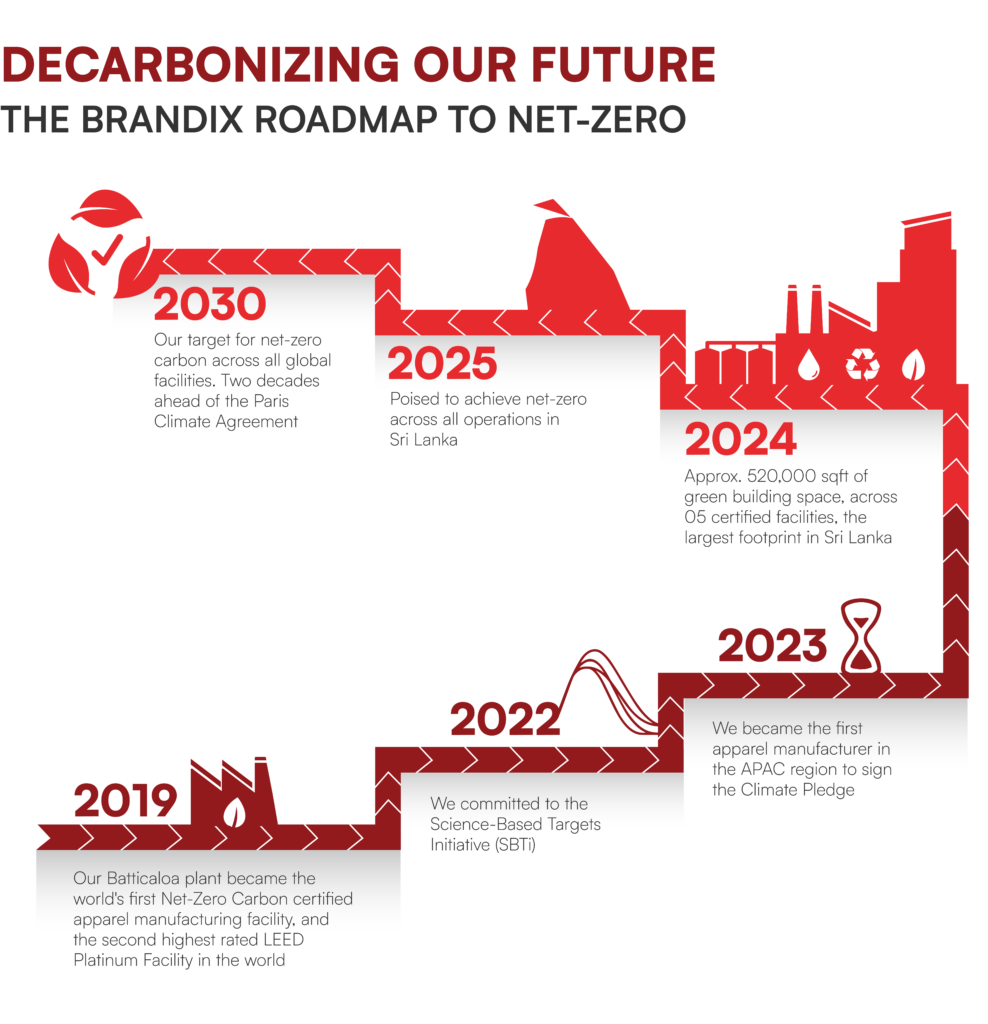

In 2019, our Batticaloa plant was named the world’s first Net Zero Carbon (across Scope 1 and 2) apparel manufacturing facility, and six more facilities have since achieved the same recognition. In 2023, Brandix signed the Amazon Climate Pledge, the first apparel manufacturer in the Asia-Pacific region to do so. The final goal? To achieve Net Zero Carbon (across Scope 1, 2 and 3) across all our global facilities by 2030, which is two decades ahead of the Paris Agreement mandate.

Beyond pioneering net-zero carbon manufacturing, Brandix hopes to inspire environmentally conscious construction within Sri Lanka’s industrial sector. We currently operate the largest green building space in the country, with a combined total of 519,042 square feet across five certified buildings. These certifications include two LEED Platinum, two LEED Gold, and one GreenMark Platinum.

A recent United Nations Environment Programme (UNEP) report paints a concerning picture of the fashion industry’s environmental impact. The industry is estimated to contribute 2-8% of global greenhouse gas emissions, 9% of annual microplastic pollution found in the oceans, and consume 215 trillion liters of water each year. Recognizing the urgency to act, we have taken a proactive approach by embedding sustainability into the very core of our business model, making it an inseparable aspect part of our daily activities.

Sri Lanka’s recent economic crisis brought home to us all, the severity of resource scarcity and rising costs. In response, Brandix stepped up to strengthen its commitment to material circularity and waste management across all operations. During the year, the company expanded its use and generation of renewable energy, reaching a total capacity of 18 MW. Additionally, Brandix made significant improvements to three of its wastewater recycling plants and two sewage treatment plants. The company also expanded rainwater harvesting, carbon sequestration, and energy optimization initiatives.

Today’s customers demand sustainable and ethical fashion, as a world leader in green apparel manufacturing, we are committed to meeting these evolving demands and upholding the highest global standards.

Designing circularity into sustainable fashion

The traditional, “take-make-dispose” linear economy is facing a challenge from a new paradigm: the circular economy. Circularity prioritizes “reduce, reuse, recycle” aiming to optimize resource use, minimize waste, and conserve precious natural resources. It also represents a powerful contribution to achieving global climate targets.

For businesses, particularly manufacturers, this shift offers significant potential benefits.

Environmental Impact: By extending the life cycle of materials and reducing waste, the circular economy helps lessen our collective environmental footprint.

Cost Savings: A report by the Ellen MacArthur Foundation estimates $700 billion in annual global material cost savings through circular manufacturing. Manufacturers are increasingly recognizing these advantages, driving the shift towards circular practices.

Resource Efficiency: Circularity reduces reliance on scarce resources. This not only benefits the environment, but also makes manufacturers less vulnerable to resource scarcity and price fluctuations.

Design Flexibility: Circular principles encourage manufacturers to create products that are more adaptable in terms of design and materials. This translates to easier repair, reuse, and eventual recycling.

The potential economic benefits are equally compelling. A McKinsey report suggests that the transition to a circular economy could unlock $2 trillion in value by 2030.

“Our strategic focus prioritizes sustainability through a multi-pronged approach: investing in renewable energy, optimizing energy efficiency, cleaner production methods, and responsible use of materials. By designing clothing for durability, reuse, recyclability, and even remanufacturing, we aim to keep our products and the materials used in production circulating within the economy and out of landfills. The future sees us decoupling production from virgin resource inputs, furthering innovation, accelerating growth, and creating more employment opportunities. Brandix is well-positioned to become the go-to manufacturer for global brands seeking a range of sustainable solutions as our core values – innovation, sustainability, and agility – align directly with the principles of circularity.

Brandix is actively exploring different methods of closing the loop in the lifecycle of clothing, from utilizing bio-based raw materials to designing products for infinite recyclability or biodegradation. These bio-based and biodegradable materials offer a sustainable alternative, with the ability to safely re-enter the natural world and return valuable nutrients back to the environment if necessary. Another focus area is the utilization of cotton waste that ingrains circular principles: recapturing value from existing materials and reducing demand for virgin resources, while minimizing waste and pollution,” says Dinush Wimalachandra, who leads Product Solutions, Research and Development at Brandix.

Is cotton the enemy of ethical fashion?

Cotton, according to the World Wildlife Fund, is a global economic powerhouse. As the most widespread profitable non-food crop, it provides income for over 250 million people and employs nearly 7% of the developing world’s workforce. However, this success story hides a dark secret: current cotton production methods are demonstrably unsustainable.

These unsustainable practices threaten the very future of the industry they prop up. Cotton production is known for its heavy water usage, with some experts claiming it is the thirstiest crop among all agricultural commodities. Diverting surface and groundwater for irrigation leads to the steep cost of freshwater loss through evaporation and inefficient water management. Furthermore, Conventional cotton cultivation relies heavily on fertilizers and pesticides, the runoff of which pollutes rivers, lakes, wetlands, and aquifers. These pollutants devastate biodiversity through immediate toxicity and long-term accumulation. Heavy use of pesticides is also a concern for the health of farm workers and nearby populations.

The consequences of cotton’s water footprint are starkly evident in major ecosystems like the Aral Sea in Central Asia, the Indus Delta in the Indian Subcontinent, and the Murray Darling River in Australia. All of which are under severe stress as a result of water diversion and pollution caused by cotton production.

Soil degradation is another major concern. Despite the global area devoted to cotton cultivation remaining constant for over 70 years, soil quality in many regions has been depleted and degraded. Intensive farming practices on established fields has led to exhaustion, forcing expansion into new areas. This habitat destruction adds another layer to the environmental cost of cotton production.

From trash to treasure: how Brandix is giving cotton waste new life

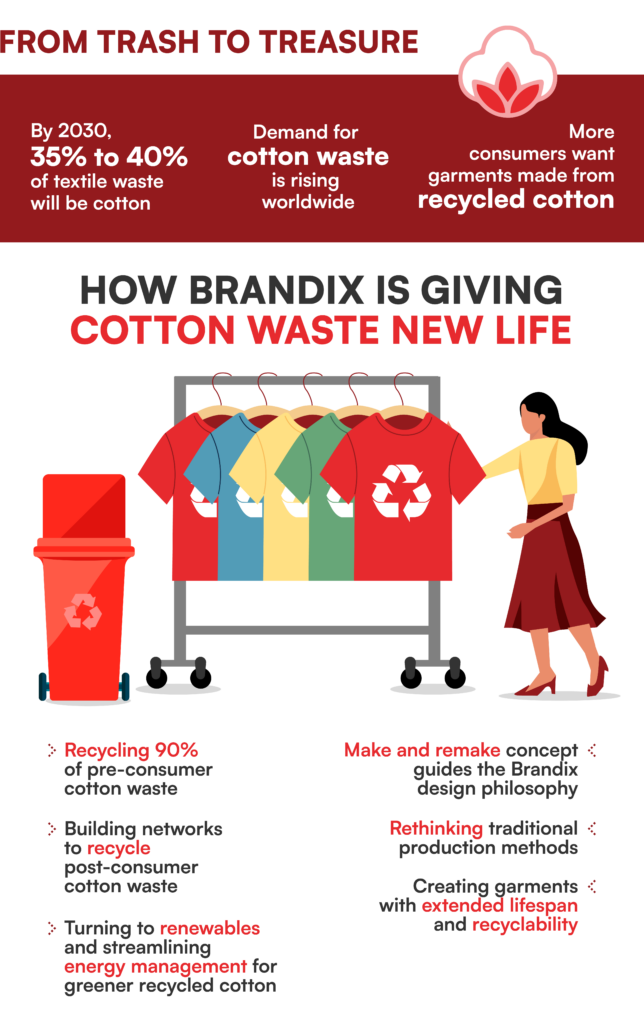

In the early days of cotton production, textile manufacturers simply discarded excess material as waste. Later, this waste found new life in other industries, transformed into products like cardboard, bricks, and upholstery. However, the challenge still persists, with the total quantity of textile waste projected to reach 148 million tons by 2030, of which cotton waste will account for about thirty five to forty percent.

The fashion industry’s current shift towards sustainability, is giving recycled cotton the spotlight. Recycled cotton can be broadly defined as transforming used or excess cotton fabric into usable fibers that can be given new life in a variety of textile products. Recycled cotton is also commonly referred to as regenerated or reclaimed cotton.

Brandix has been able to successfully integrate recycled cotton into the company’s product portfolio by using 90% of cotton cut waste. Scraps of yarn and fabric by-products are turned into high-quality yarn and ultimately sustainable apparel. While this is the primary source, the company is constantly exploring ways to further reduce waste and increase resource independence. This includes finding innovative approaches to turn even more cut and knitting waste into recycled cotton.

Going even further, Brandix is exploring the potential of a “post-consumer” source for cotton waste – discarded garments that can be repurposed into new products. However, accessing post-consumer waste presents a unique challenge. Unlike manufacturing waste, it relies heavily on participation from the end-users, the consumers. To address this, we are in discussions with the brands we supply to develop collection and reverse logistics systems that encourage consumers to return used clothing and textiles.

Once used garments are received, the recycling process begins. Sorting post-consumer waste is particularly labor-intensive due to the vast variety of colors, fabric blends, and even smaller components like sewing thread and traces of spandex. Each of these elements needs careful consideration and categorization before the material can be reintroduced into the recycling stream. This new avenue has, in turn, created demand for different business services requiring specialized knowledge and expertise.

After sorting, machines are used to shred the fabric into yarn and then break it down further into raw fiber. This rough processing often results in breakages and entanglement, which can lead to a decrease in the strength and quality of the fiber. The shredding process can also impact fiber length and uniformity, potentially limiting end-use application. The raw fibers are then spun back into yarns to create new textiles. Brandix is actively experimenting with methods to improve the quality of recycled fibers, aiming to achieve results that equal or even surpass the quality of virgin fibers.

Today’s consumers are increasingly more conscious of environmental impact, prioritizing products and services that employ sustainable practices. This shift in consumer behavior is pushing manufacturers to find innovative ways to keep materials in circulation and out of landfills.

Brandix is embracing this movement. The concept of “make and remake” guides our design philosophy. We are also rethinking traditional production methods and creating garments designed for extended lifespans and recyclability.

Authored by Kamaya de Soysa