Cleaning Up the Clothes We Wear: Sustainable Fashion’s Battle Against Microfiber Pollution

It is no secret that our planet is in trouble. Every day brings us closer to a major environmental crisis. Many of us are also aware that one of the biggest threats we face is from plastic pollution and we try to do our part by saying no to single-use plastics like disposable straws, water bottles and shopping bags; opting instead for reusable alternatives. If enough people do this, it can dramatically cut down volumes of plastic waste. However, there is another problem we need to understand and tackle urgently; and it is hiding in the clothes we wear every day.

As the human population continues to grow, so does the fashion industry. The fast fashion business model has fueled an enormous increase in clothing being produced, sold and discarded. According to a study done by McKinsey, clothing production doubled from 2000 to 2014. During this time, the average consumer bought 60% more garments each year, but kept them for only half as long as they did just 15 years prior. This translates to an incredible 100 billion items of clothing being produced annually – nearly 14 items for each person on Earth; with at least 3 out of 5 articles of clothing being disposed of within a year of being produced and sold.

“Brandix understands the significant environmental impact of the apparel industry,” says Dinush Wimalachandra, General Manager for Product Solutions, Research and Development. “Which is why sustainability is a core pillar of our strategy. As leaders in this field, we have made it our responsibility to continuously drive positive change and use our influence to create a more eco-conscious future for fashion.”

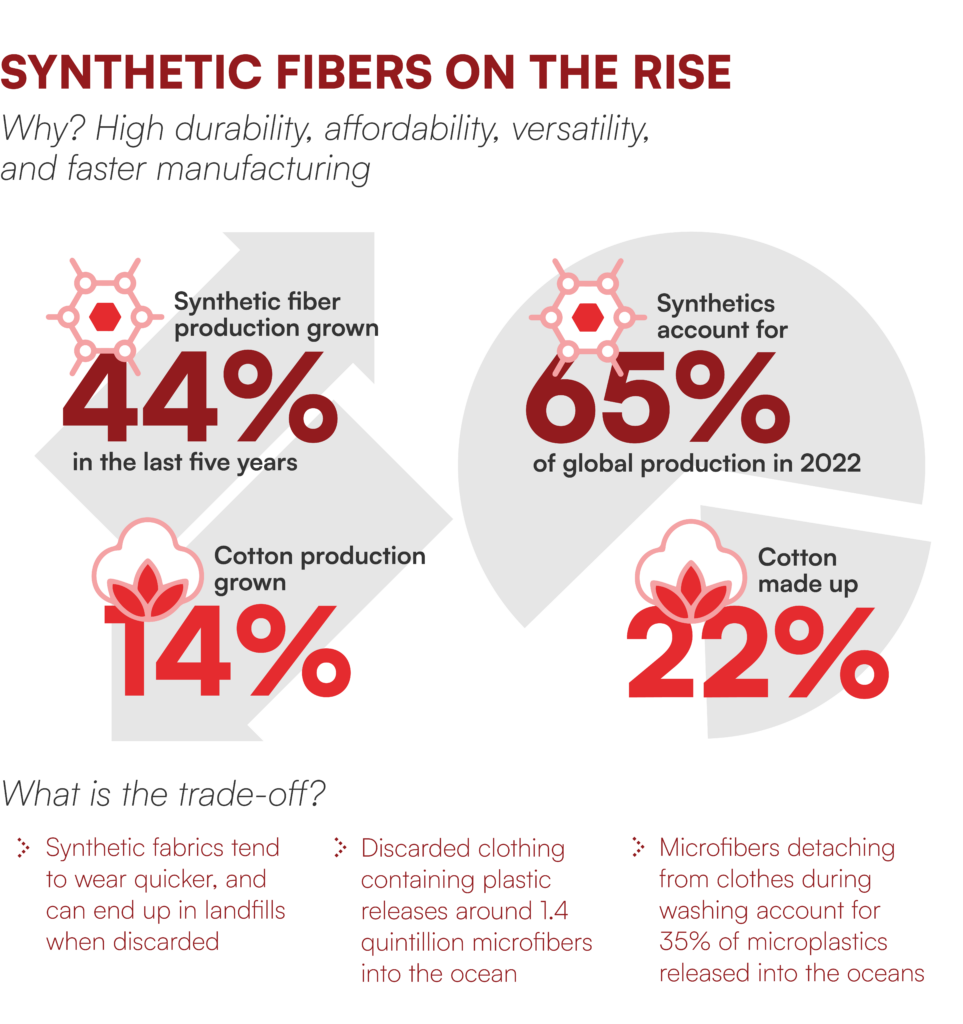

Today, the textile industry is undergoing a seismic shift: cotton-based fabrics are being rapidly replaced by non-cotton-based products, particularly synthetics, which is evident in the dramatic growth rate. Synthetic fiber production has climbed by 44% in the last five years, while cotton has only grown by 14%. This trend can be attributed, at least in part, to the high durability and affordability synthetic fibers offer. This makes them extremely versatile for clothing and textile manufacturing. Synthetic clothing or petroleum-based fabric is what we know as: polyester, nylon, acrylic, spandex (also called Lycra or elastane), fleece, or polyolefin. Synthetics dominated the fiber market in 2022, accounting for 65% of global production, according to Statista. Polyester, the king of synthetics, made up 54% of the market share. In comparison, cotton sat at a distant 22%, with other natural plant-based fibers holding a mere 5%.

However, there is a hidden cost to this convenience: synthetic fibers contain some percentage of manmade material, most often, plastic. The Plastic Pollution Coalition revealed, nearly 70 billion clothing items produced globally contain some form of plastic, with production output only expected to increase in the future.

So, what’s the issue with plastic in our clothes?

Plastic acts as a carrier for a multitude of potentially harmful chemicals added during the manufacturing process. Studies reveal that plastics can contain a complex mix of over 13,000 different chemicals, with more than 3,200 of these being classified as hazardous. These chemicals include BPA, phthalates, and PFAS.

Clothes made from synthetic fabrics tend to wear quicker than those made from natural fabrics, leading to them being used and thrown away in a shorter amount of time. When discarded, these items can end up in landfills, polluting the air, soil, waterways and oceans. Discarded clothing containing plastic alone is estimated to release at least 1.4 quintillion (or a million trillions) tiny fibers, known as microfibers, into the ocean.

“We recognize that microfiber pollution is a serious threat,” explains Wimalachandra. “There is an urgent need for the apparel industry to take action. Brandix is proactively implementing measures to safeguard the environment, focusing on cleaner air, water, and a healthier planet.”

What are microfibers?

Each time an article of clothing is washed, whether synthetic or natural, it sheds millions of microfibers into the wastewater. The microfibers found in textiles usually contain chemical additives, from the manufacturing process, such as plasticizers (added to improve elasticity of the material), or antimicrobial agents. They can also absorb chemicals present in the water or drainage systems, such as Polychlorinated Biphenyls (PCBs) and Persistent Organic Pollutants (POPs), many of which are known carcinogens. Most present day washing machines are not equipped to catch these small fragments, nor are drainage systems, which leads to them finding their way into rivers and, eventually oceans.

In the case of synthetic clothing, the microfibers that detach from clothes during washing are a type of microplastic. 35% of microplastics released globally into the oceans is estimated to come from the seemingly simple act of laundering our clothes. Chemicals leaching from these synthetic microfibers can enter the bloodstream of animals that ingest them, leading to a range of health problems. The effects of microplastic ingestion on marine life are catastrophic. Microplastics have been linked to damaged digestive systems, starvation, endocrine disruption, and stunted growth in some species. While the consequences for marine ecosystems are dire, it is even more concerning that these same particles have found their way into our own digestive systems.

Disturbingly, microplastics have been detected in everyday food and drink items, including bottled water, tap water, salt, and even beer. Studies estimate that each person unknowingly ingests 14,000 to 68,000 plastic microfibers every year.

Additionally, natural fabrics, like cotton and wool, also shed microfibers. Some microfibers are small and light enough to stay afloat in the air. Scientists have only recently detected microplastic particles in the lower airways of humans. This means we are not just ingesting these tiny textile fragments through food and water, we are also inhaling them. This finding significantly expands the scope of microplastic exposure and raises questions about its potential impact on our respiratory health. One study revealed that in a household, 33% of microplastics in floating dust came from synthetic fabrics. Researchers approximate we inhale a credit card’s worth of plastic particles per week through airborne dust. Microplastics are all around us, and have been found in human bloodstreams and even breast milk.

What’s being done to combat microplastic pollution?

Once these tiny plastic fibers enter our waterways and ecosystems, their removal is extremely difficult. They can persist for years, presenting a long term environmental challenge. The World Health Organization has called for more attention to be paid to the dangers of microplastics.

Global initiatives like The Microfibre Consortium, based in Bristol, England, are fostering innovation to tackle the problem. In September 2021, the Consortium launched the ambitious Microfibre 2030 Commitment, aiming to rally 80% of its signatories – including leading brands like Adidas, Gap, Puma, and Under Armour – to adopt specific microfiber reduction limits by 2030.

The nonprofit is going beyond setting ambitious goals. To ensure accurate measurement of microfiber shedding, they have developed a publicly available test method: the Microfibre Consortium Test Method. Validated by ten independent international laboratories, this method simulates home laundry cycles and incorporates eight repetitions for reliable results. The collected data is then fed into the Consortium’s Microfibre Data Portal, paving the way for a future global rating system for microfiber shedding within the textile industry.

Adding to the global effort is the Cross Industry Agreement (CIA). This initiative brings together five European industry associations representing the entire lifecycle of garments, from production to washing and care. United by a common goal, these voluntary collaborators are working towards preventing microplastics from entering aquatic environments when synthetic textiles are laundered.

The fight against microfiber pollution extends beyond industry initiatives. Governments are also taking action. The European Commission has pledged to tackle microplastics, including those originating from apparel. France will take a pioneering step next year by mandating new washing machines to include microfiber filters.

Consumers also play a crucial role. The National Environmental Education Foundation offers practical solutions to reduce microfiber shedding at home. These include opting for cold water washing cycles, minimizing the frequency of washing clothes, and installing microfiber filters in existing washing machines.

How are apparel manufacturing companies getting in the game?

The textile industry sits at the heart of economic progress, an essential part of our modern world. Yet, as a global manufacturing giant, it also presents some of the most complex environmental challenges we face. However, within this same industry lies immense potential for the most impactful positive environmental change.

“To accelerate progress on fiber fragmentation, the textile industry requires a unified front. Brandix is setting the standard by forging strong partnerships with leading sustainability initiatives. Through this collaborative effort, we can move beyond individual initiatives and enact coordinated, impactful change that benefits both the environment and the industry’s long-term sustainability and social responsibility,” says Wimalachandra.

Knowledge sharing is key in the fight for a healthier planet, and Under Armour is walking the walk, not just talking the talk. In 2023, the global sportswear giant partnered with James Heal, a leader in precision testing solutions, to develop and launch a groundbreaking fiber-shed test method. Moreover, Under Armour is not keeping this innovative solution a secret. They are making their optimized test kits, utilizing a simplified and repeatable method, available for industry-wide use. These kits offer a fast, cost effective way to assess fiber shedding, a significant improvement over the time-consuming and expensive processes previously used in research and development.

Under Armour’s commitment goes beyond public availability, they have also provided complimentary test kits to high-volume textile mills within their global supply chain, to encourage early intervention across their entire production network.

The Brandix Blueprint: fashion and sustainability

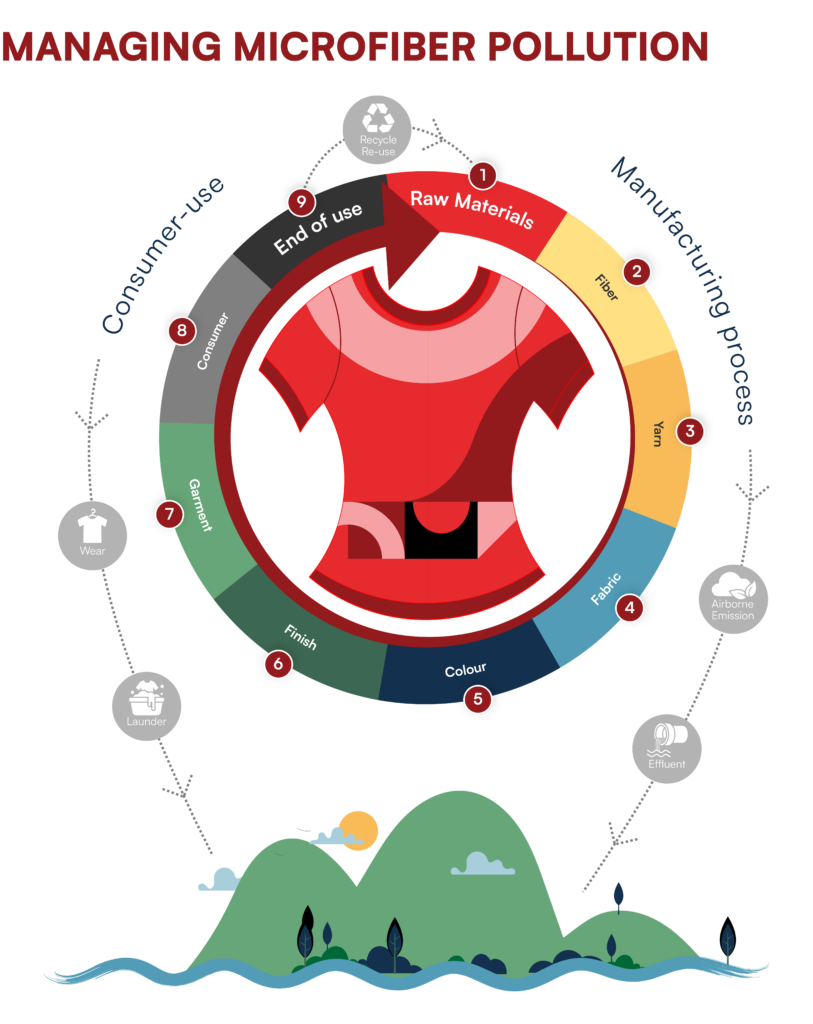

“Eliminating or even reducing microfiber pollution is no small feat, but Brandix is not shying away from the challenge. We are committed to tackling this issue head-on through a multi-faceted approach that leaves no stone unturned. Our in-house innovation team is actively looking for methods to minimize microfiber shedding by critically evaluating every stage of our production process. We also partner with leading material scientists, environmental engineers, and research institutions to leverage diverse expertise. By pinpointing the most significant sources of shedding, we can strategically implement solutions for maximum impact,” says Wimalachandra, who is also a valued member of the Brandix innovation team.

“Our fight starts at the source and ends when a garment is disposed of sustainably or recycled. This includes exploring new materials, optimizing existing processes, developing filtration technologies and more. We are currently working to create a new bio-based raw material that will be completely free of plastic. Several ideas are also being explored throughout the industry: brushing techniques, laser and ultrasound cutting, special coatings, and pre-washing garments. Factors like length of the yarn, type of weave, and methods for finishing a seam are also being looked at in relation to how they impact shedding rates. Another promising approach involves specialized machinery that would absorb or extract microfiber from garments before they are released to the market.

Despite being a prevalent topic within the industry, it may not be a danger that many end-users are aware of and the consumers’ actions are the final piece of this puzzle. As a manufacturer, we have a responsibility to create awareness. We can start to do this by providing instructions through labelling but Brandix is also looking at other creative ways to get the message out there. It is up to companies like ours to take on a pioneering role and set an example as responsible stewards of the environment.

While further research is essential to identify best practices and establish industry-wide solutions—a cause in which Brandix is deeply invested—the textile industry has an opportunity to act now and make an impactful difference. What we do today will be a pivotal step in moving the industry towards a more sustainable future.”

Authored by Kamaya de Soysa